As we reported in December 2016, there is both good and bad news on the horizon in 2017; it will be interesting to see whether or not the current rising rates are the vortex of a typhoon, or the calm aftermath of a tsunami. Certainly "imbalance" is the key word for this industry and trade as a whole. Shipyards are definitely suffering from a lack of balance.

Overstaffed Shipyards With Little Demand

A serious part of the shipping world's imbalance comes from the Chinese and S. Korean shipyards. These shipyards are grossly overstaffed, and taking orders for ships at prices that guarantee a loss but keep people working – or at least marginally employed. Other than oil, Parastatel industries typically don't succeed in a free market economy, and when looking at the record of China's steel, cement, aluminum, and shipbuilding industries, these don't succeed in China's semi-regulated economy either.

Concern is mounting about whether South Korean shipyards will be able to repay record amounts of debt coming due in 2017. Last month Bloomberg reports the top four Korean shipbuilders owe US $ 1.9 billion (2.3 trillion won), and are rumored to be unable to make the payments without government aid.

While Samsung Heavy Industries will have enough cash to meet obligations after a recent rights issue and because it expects to deliver an offshore oil facility, Daewoo Shipbuilding likely will not. DSME is selling non-essential assets including subsidiaries and real estate in order to meet their upcoming obligations, and are expected to receive an additional $2.4 billion in capital from its biggest shareholder, the state-run Korea Development Bank, and also the Export-Import Bank of Korea. However, both the sales and the capital infusions will likely prove insufficient as they have fewer ships and oil rigs on the order books. Both Samsung and Hyundai Heavy Industries have similar weak order books.

Low Vessel Prices. More Ships. Extra Capacity. Ugly Spiral.

All the shipyards have incurred multiple quarters of losses in the past 18-24 months due to a deadly combination of postponed orders and a plunge in demand for new vessels and oil platforms.

Chinese and Japanese shipyards also have been affected. Cosco Singapore, which is owned by a Chinese company and has its shipyards on the mainland, saw bulk-carrier orders canceled as slower commodities demand in China has led to overcapacity and the decline in the Baltic Dry Index that affected rates and therefore profitability. HI Corp., co-owner of Japan’s second-largest shipbuilder, lowered its net income target for the year while Mitsui Engineering & Shipbuilding Co. also cut its forecast.

Similar to the 20% cargo versus container imbalance that continues to affect box rates; too little demand for newbuildings forces shipyards to offer vessels at prices that entices carriers to buy unneeded vessels that serve to drive rates downward. This is an ugly spiral.

Related Reading

Aberdeen Exclusive Report | Best-in-Class Shippers Gain Visibility into Container Shipping

How to Gain Transparency into Ocean Freight RatesBig Volume Shipping No Longer Means Big Value Rates

The good news comes from Antwerp, where the port authorities reported a record year in box cargo, exceeding 10 million TEU's in 2016. Final results are 10,056,603 TEU's, a 4.2% increase over 2015, carrying 117,979,603 metric tons.

Unknown however, is how much of this cargo comes at the expense of Hamburg-LeHavre-Rotterdam ports due to 2M, Ocean Alliance, and THE Alliance lane and scheduling changes that give Antwerp a stronger position in the Asia – N. European Range trades while taking advantage of the cost savings and economies of scale offered by the Megas.

Whether in containers or the ships hauling the containers, bad things happen unless Supply and Demand is roughly balanced. 2017 is looking to be an interesting year.

[Live Webinar] Jan '17 | Ocean Freight Rates Review

Join us on January 17th, 2017 as we analyze container shipping prices for the main global routes as reported in the Xeneta platform.

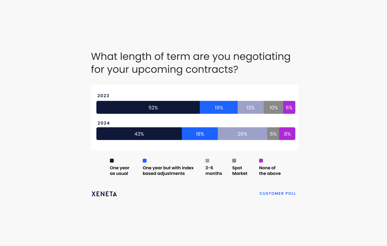

- Q4 2016 saw start of ocean freight rate negotiations in Europe. North American companies will begin in early 2017. What should you be on the lookout for during your 2017 negotiations?

- Q1 2017 and beyond – How are long-term contracts for 2017 affected by 2016 industry happenings?

- What correlations are there between the spot market price activities and the long term?