Retail shippers must act immediately to improve their performance in the volatile ocean freight market. Over the past year, retail shippers have consistently paid higher spot rates on major shipping routes than all other shippers. Compounded by sluggish US and European demand, high warehouse inventories, and narrow profit margins, this situation demands swift attention, even while we remain in a weak buyer's market (although this is also shifting).

Market dynamics are in constant flux, with rates varying widely across trade lanes due to capacity management and disruptive events like the Panama Canal drought and port strikes. To navigate this turbulence, retailers must harness market data to align their freight spend with the market averages. The urgency is clear: waiting is not an option for retailers.

How can you steer through these fluctuations to stabilize your freight spend during this pivotal window of strategic adjustment?

5 Fixes for Retail Shippers’ Above-Market Rates (Choose any or all that apply)

1. Time your contracts to the market

Determining the right time to run a tender, renegotiate a contract, and play the spot market are crucial decisions for retail shippers. Questions you should be asking yourself: How much longer can I expect the market to stay low? If I lock in long-term contracts right now, will I still be happy with my rates in six months? Which of my trades have seen lower rates for three+ months on the spot market? Don’t settle for contracts that are “good enough,” fight for every dollar and ensure your strategy holds up against market changes.

2. Identify market risks and opportunities

We’ll say it again in case it hasn’t fully sunken in—since Q4’22, retailers have consistently paid more for spot rates than all other shippers across several main corridors. Based on our conversations with retail shippers, many don’t even realize this. While the delta varies across trades, it’s safe to say this is costing retailers precious profits.

.png?width=820&height=539&name=image%20(6).png)

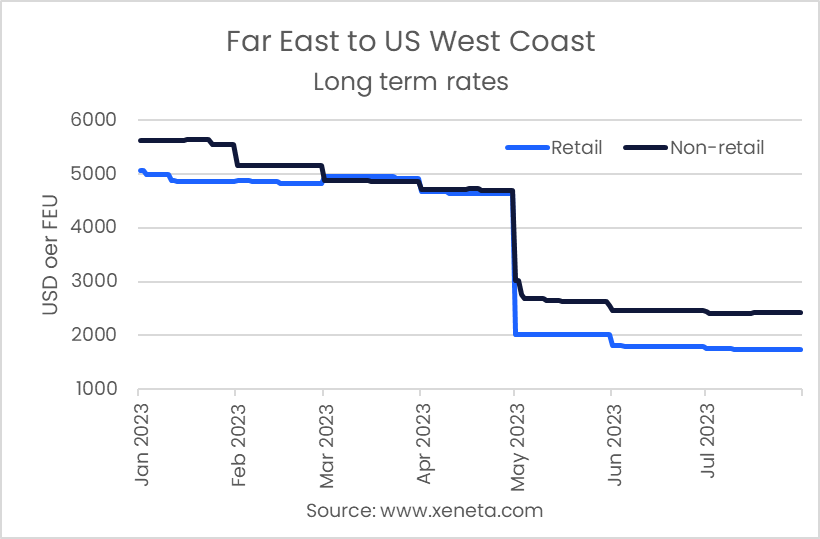

Far East - US West Coast (above) shows this discrepancy very clearly in the first half of the year, with the gap now narrowing. Alternatively, on Far East - South America East Coast (below), retailers were initially below the market average, but are now slightly above. The first corridor could be an opportunity to capitalize on, while the second is one retail shippers should keep an eye on. Want to know other corridors where this delta exists? Get a peek behind the curtain with Xeneta data.

3. Get better rates than your competitors

Even more than other shipper types, retailers primarily want to know how their performance compares to their closest competitors, particularly those at a similar volume level. While there is an abundance of market data available on overall performance, freight spend is one metric that remains opaque. This is why retail shippers must ensure their market data sources have the depth and breadth to provide as close to a peer analysis as possible. This includes:

- Various container types to weed out those who may have a different commodity or product type

- Global port-to-port rate coverage to drill down into your exact trade lanes and regions

- Ocean and air freight data, as many retailers utilize both

With data this granular, retail shippers can benchmark against a segment of shippers that closely reflects their own business, rather than an entire market of businesses that may not have similar challenges, limitations or goals.

4. Bounce back from low demand and high inventory levels

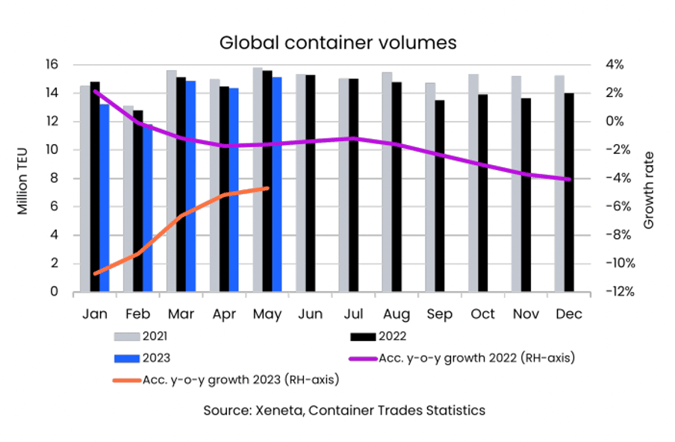

As consumer behavior has changed post-pandemic, retailers have been hard hit by decreased demand and increased inventory levels. Demand for imports continues to be very low in the US, the world’s largest consumer market, despite retail sales growing by 2.2% over the first five months of 2023. This is in part due to inflation, meaning that in real terms, retail sales have actually fallen slightly year on year.

If the market were to see an increase in demand for containerized goods, it’s crucial that shippers first clear existing inventory. Ocean carriers and freight forwarders understand this dynamic and are adjusting rates accordingly, causing retail shippers to pay a premium to fill capacity.

With lower volumes than previous years, retail shippers should watch the market and maintain data-driven supplier relationships to get favorable rates and service levels.

5. Champion sustainability on behalf of your customers

In an era where sustainability is a top priority for consumers, retailers are increasingly focused on reducing carbon emissions within their supply chains. By tracking the carbon intensity of carriers, retail shippers can align their ESG goals with their freight procurement strategies, fostering a more sustainable supply chain that consumers can get behind.

As retail shippers are particularly vulnerable to macro-events and consumer behavior changes, it is essential to create a procurement strategy that is agile and proactive to potential disruptions. Having a clear source of market intelligence will tell you which of your trades are experiencing spikes or dips so you can take action. Should you lock in long-term contracts where rates are low? Divert cargo from lanes where rates or congestion are high? These are decisions that can’t be made without visibility, but with Xeneta, retail shippers have the granular data they need to answer all the above challenges and more.

Xeneta partners with some of the world’s largest and most successful global retailers, including Ralph Lauren, L’Oreal, Nestlé and Crocs, which rely on Xeneta’s data granularity, complexity and global port-to-port coverage to get the peer comparison they need, select the best type and timing for contracts, and bring their rates down despite low demand and high inventory. Contact us if you’d like to learn more about what a partnership with Xeneta could look like.

Want to learn more?

Contact us to learn how Xeneta can help you prepare for supplier/buyer negotiations and gain the upper hand with actionable real-time ocean and air freight rate and capacity data.