If there was one theme that stood out at TPM25, it’s this: supply chains are no longer just unpredictable, they’re unthinkable. From Red Sea diversions to tariff whiplash, the past five years have forced logistics teams to rethink their strategies in real time.

Those who fail to adapt risk being left behind.

At Xeneta, we thrive on making sense of market chaos. And TPM25 was the perfect place to take stock of where the industry stands – and where it’s headed next.

Air Cargo: A Safety Net, But at What Cost?

Ocean freight may still be king, but for many, air cargo has become an essential safety net.

During the panel “Air Cargo: Make It Part of Your Supply Chain or Pay the Price”, most attendees admitted to making unplanned air freight moves in the past year to combat ocean delays. And while rates are currently falling as ocean reliability improves, the future is still a question mark. If e-commerce slows or Red Sea routes reopen, air rates could swing dramatically downwards.

As Prathibha Hampapur from Lululemon put it: Air cargo brings predictability in unpredictable times. You can always find capacity, but can you find it at the right price?

For businesses, this presents a tough decision:

- Ship by air and maintain full price?

- Or risk ocean delays and discount products later?

For e-commerce brands with seasonal products, that’s a make-or-break choice. And it’s not just retail. Industries like AI and semiconductors, which rely on scarce materials, are leaning on air freight to avoid production bottlenecks.

Red Sea Crisis: When Will It End?

Xeneta’s own Senior Shipping Analyst, Emily Stausbøll, took the stage in “Trade Lane Focus: Is Relief in Sight for Asia-Europe Shippers?” to unpack the lingering impact of Red Sea diversions.

The numbers tell the story. Over the past five years, freight rates have been on a rollercoaster – with two key surges: the pandemic and the Red Sea crisis. Right now, the spread between long- and short-term rates is narrowing, and softening spot rates could soon trickle into long-term contracts.

But what happens when (or if) the Red Sea stabilizes?

With capacity already inflated by 40% (compared to 2019), shippers may face an entirely new dynamic as rerouted cargo finds its way back onto traditional lanes. Will carriers be ready? More importantly, will they be willing to adapt pricing models to reflect a post-crisis landscape?

Tariff Whiplash: A Political Game of On/Off

Trade policy has always been volatile, but right now, it feels like somebody's flipping switches on and off, and back on again.

The latest tariff uncertainty – especially with the new Trump tariffs – has businesses hesitant to act. We’ve seen this before. When tariffs were imposed on China previously, furniture and machinery exports took a hit, while low-value, high-volume products like toys kept flowing. Vietnam, on the other hand, saw a boom in furniture exports.

This year’s panel discussions emphasized diversifying export routes beyond China, with India, Thailand, and Vietnam emerging as growing contenders. While alternatives exist, relocating an entire supply chain (or even just parts of a supply chain) can be a monumental task, involving new suppliers, factory setups, workforce training, and navigating different regulations and cultural practices. It's not surprise then, that many companies are choosing to play the waiting game.

But as history has shown, waiting isn’t always the safest strategy.

The Supply Chain Wake-Up Call: Planning for the Unthinkable

McKinsey’s latest research is worrying: 90% of supply chain leaders faced resilience challenges in 2024.

At TPM, a simple show of hands confirmed this. Very few companies in the room had a documented contingency plan. And yet, failing to prepare means preparing to fail. A US automotive manufacturer learned this the hard way, when a missing 10-cent part nearly shut down operations.

So what’s the solution? Leading companies are taking a proactive approach:

- Paying slightly more for freight to work with multiple logistics providers, rather than relying on one.

- Mapping out supply chain dependencies and stress-testing them against unlikely (but possible) scenarios.

- Moving beyond cost-cutting to prioritize resilience – because the cost of a shutdown is far greater than the cost of flexibility.

The takeaway? If you think the worst-case scenario will never happen to you, think again.

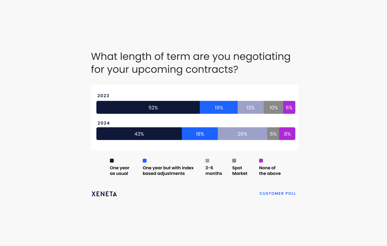

Index-Linked Contracts: The Industry is Finally Catching Up

For years, index-linked contracts were met with scepticism. Now, they’re becoming a necessity.

Driven by volatility, these contracts are no longer just about price protection – they’re about reliability. Shippers need stability, and carriers need predictable revenue. By linking rates to an agreed index, both parties avoid endless renegotiations and can focus on securing long-term stability.

It’s also not just about sharing spend anymore – CFOs are pushing procurement teams to forecast freight costs years in advance. And with machine learning and predictive analytics gaining traction, forward-thinking companies are taking advantage of freight outlook forecasting to get ahead.

The innovators have already proven that index-linked contracts work. Now, the rest of the industry is starting to follow suit.

The Bottom Line

TPM25 made one thing clear: resilience is now the ultimate currency in supply chain management.

From air cargo to trade tariffs, the industry is in a constant state of flux. Companies that embrace flexibility, plan for the unthinkable, and leverage data-driven strategies will not only survive – but thrive.

At Xeneta, we help businesses navigate this volatility with real-time market insights, ensuring they’re always one step ahead. Because in today’s supply chain, waiting for stability isn’t an option.

If you're ready to invest in supply chain resilience and flexibility, book a personalised demo of Xeneta today.